How does a pump get into the cloud?

Many customers of Herborner Pumpentechnik are occupied with the desire to retrieve and use information about pumps, at any time from any place. Up until now, there have been solutions that were valid in theory, but not successful in practice. HP.MIND, the in-house Herborner HP.IOT controller, now delivers both a future-oriented and sustainable solution.

HP.IOT controller – the perfect symbiosis

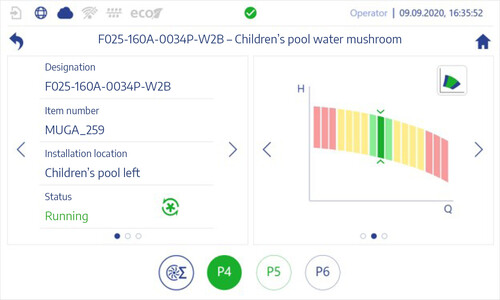

HP.MIND combines two systems and thus provides an optimum solution for the customer. The foundation for this solution is formed by the gateway that connects the pump with the “Internet of Things” (IoT). To do this, HP.MIND collects information from the connected pumps and sends this in encrypted form to the cloud solution developed by the company’s own IT department. With this, HP.MIND not only records pump information, such as delivery rate, delivery head, speed, etc., but also transmits various events, such as a dry run of the mechanical seal, a short-circuit or even information for cleaning the prefilter of the swimming-pool water circulation pump. Such information can be called up on the HP.MIND on-site using the 7″ color touch display as well as in the HP.IOT portal in the cloud. Furthermore, the HP.IOT controller can be used as a full-featured programmable logic controller (PLC) to automate smaller systems. Of course, the device can also be combined with water value monitoring or controlled via an intelligent timer.

The hardware – optimally suitable for harsh environments

The HP.MIND housing, with its IP65 classification, resists almost all environmental influences. In order to supply the customer with the best possible device, Herborner Pumpen and its partners have jointly developed and designed the hardware. This resulted in a device that is tailor-made optimally to customer requirements and, in addition, offers a high degree of safety. High-quality M12 connections provide a simple and secure connection of a wide variety of sensors and actuators. Modular IO-modules simplify the adaptation of the device to diverse customer needs.

HP.MIND in use

HP.MIND is always supplied preconfigured, so that the startup is done via plug-and-play. The cloud functionality forms the basis of every installation, which is designed so that existing systems can be expanded with it. In this way, pump systems can be analyzed and optimized, which minimizes both costs and the use of resources. The information is analyzed both on the device and in the HP.IOT portal. Integration in existing control systems or the use of HP.MIND as a “small” swimming pool control system is possible as an option.

The system is delivered together with an LTE network for communication with the cloud. Only in this way can a stable and secure Internet connection be ensured regardless of environmental conditions. For Herborner Pumpen, a maximum degree of data security goes without question. The HP.MIND and associated network architecture are tested and certified by TÜV Hessen and additionally by an IT security company. The security mechanisms significantly exceed the current security standard of other systems.

For the daily routine, HP.MIND most of all means a reduced workload. It is no longer necessary to go to the pump cellar, since all the important information is always visible on each terminal device. The energy costs of the individual pumps are processed and visible at a glance. The condition of the prefilter is no longer an unknown. The pump now only requires attention when there is a specific job to be done. Intelligent suggestions for optimization help to make the system more efficient.

HP.INTELLIGENCE – the digital age for pumps

In a time in which resources are becoming more and more scarce and thus increasing in value, it is essential to use all possibilities for optimization in order to be more efficient. The simple principle apples here: The more information is available, the more and better optimization can be undertaken.

HP.MIND is the key to this new, digital and thus user-centered world. This new world is called HP.INTELLIGENCE in Herborn. The digital innovations of Herborner Pumpentechnik are summarized under this generic term. Included in this is the HP.IOT portal, which makes the information usable. The portal makes various information and help available for this purpose. For this purpose, the portal offers different tips and aids that can help to retrieve the information at any time. Thus, simple questions, such as “Are my pumps still running?” and also complex jobs, such as creating energy evaluations, can be dealt with conveniently and simply. In the future, it will also be possible to make modifications to the system directly via the portal.

The goal is to help the customer operate the system as efficiently as possible. This includes, on the one hand, the optimization of operating conditions, which lower energy costs. For example, HP.MIND can recognize whether there is a pump that is better suited for the respective pumping job. On the other hand, the increase in the accessibility of the pumps plays a central role. For this, time-critical errors, for example a dry run, are signaled directly by HP.MIND, thereby protecting the pump. Long-term analyses enable condition-based maintenance, so that service calls can be planned and minimized. HP.INTELLIGENCE is further proof of the innovation of Herborner Pumpen and underscores once again the future-oriented approach of the family-owned company.

Find out more about HP.MIND

published on 03.08.2021, Herborner Pumpentechnik GmbH & Co KG